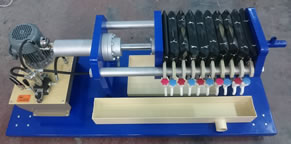

Filter Press

What is a Filter Press?

Filter press; is a mechanical filtration equipment that enables solid-liquid separation of pumpable viscosity fluid, containing solid particles. This filtration process should be done under high pressure conditions through plates and cloths.

The technical specifications of the filter press vary according to the needs of our customers.

How Filter Press Works?

Filter press operates by filtering of solid-liquid mixture sludge, fed by high-pressure pumps, through filter cloths covered over filter press plates, and thus accumulation of solid particles among filter plates and removal of the liquid phase out of the equipment.

The cloths used in filter press equipments can be made of polypropylene, cotton, chopped fibre, or other raw materials according to the physico-chemical properties of the solid-liquid mixture to be filtered.

The high-pressure pumps that feed materials to the filter press can be selected from air diaphragm pumps, mono-pumps, oil gear pumps, or lobe pumps. Pumps operating via centrifuge are usually not preferred in filter press systems.

Dewatering ratio is higher in filter press equipment compared to its equivalents such as decanter and belt press equipments.

Feeding is made by pressurizzed pumps in the form of plates compressed by high hydraulic pressure.

The solid substances accumulating in the volume in between the plates are removed by opening the plates.

Cake discharge is designed as manual or automatic according to system requirements and customer preferences.

Cake discharge is designed as manual or automatic according to system requirements and customer preferences.In addition to treatment plants, filter presses are used in various other industries such as mining, oil filtering, marble, chemistry, silicate, acid filtering in plating baths (zinc-phosphate), and food etc.

Filter presses are divided into 3 groups according to their plate compressing characteristics as manual, semi-automatic, and full automatic filter presses.

They are also divided into three essential groups based on their plate characteristics such as chamber-type plates, solid-hollow type plates (frame&plate), and chamber+membrane plates.

Solid-hollow plates are generally preferred in oil filtering (olive oil, sunflower oil, industrial oil etc.), food, and petro-chemistry sectors.

Chamber-type plates are used in the filter press units of mineral, marble, treatment systems, treatment plants, zinc phosphate coating etc. facilities.

Filter press cloths (filter cloth) have significance in filtering operation. Therefore, selection of cloths should be made appropriately according to the relevant sector. Filter press cloths are required to be washed with pressurized water at certain intervals in order to extend their expected lives.

In addition to making standard filter press production, City Makine also produces sector-specific filter presses with desired sizes, properties, and fair prices.

Our standard plate dimensions; Please click for filter press plate table>>

- 1250x1250 mm

- 1000x1000 mm

- 800x800 mm

- 630x630 mm

- 500x500 mm

- 400x400 mm

- 250x250 mm.

Click to see the digital catalogue of our filter press equipment.

Advantages of Filter Press

- High dewatering ratio,

- Low initial investment and operating costs,

- Easy service and maintenance,

- Ease of selection according to sectors,

- Optional durability/tolerance against acidic and alkaline liquids.

City Makine filter presses have been safely used in Turkey, Russia, Romania, Macedonia, Slovenia, Syria, Iraq and many other countries for many years.

For detailed information, please call us at +90 212 909 5461 or email us at info@citymakine.com.